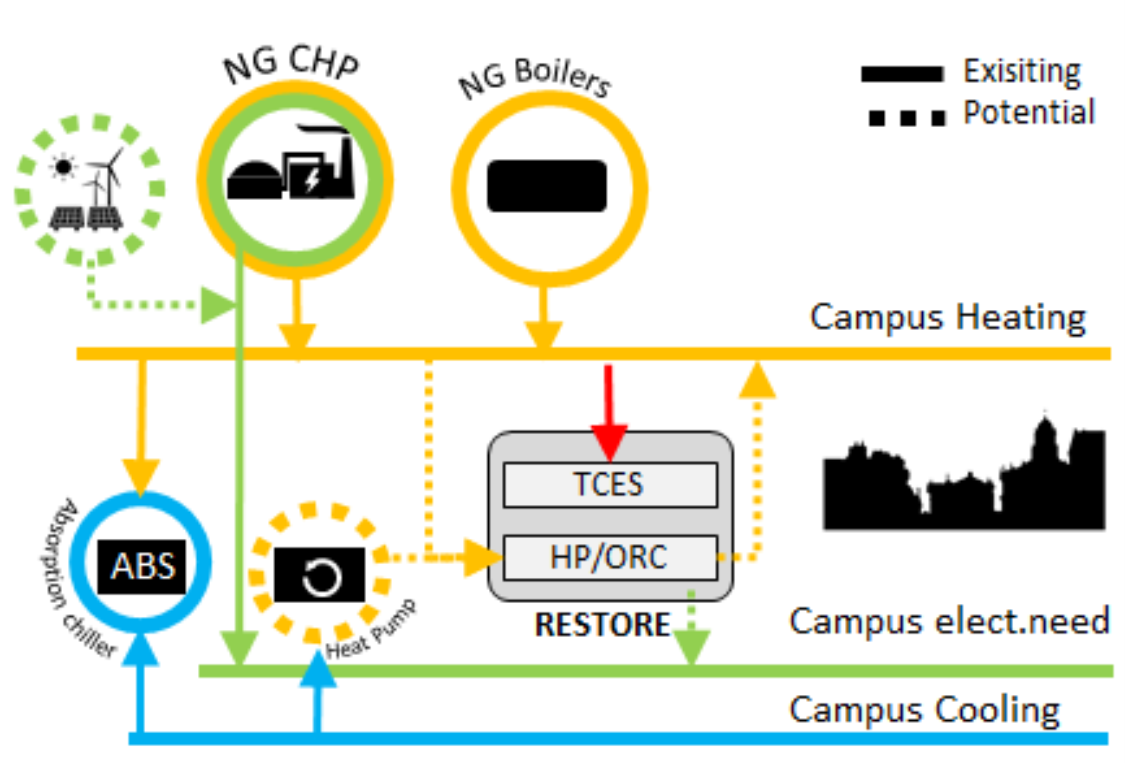

Use Case 6: RESTORE Integration

General

Politecnico di Milano’s Leonardo campus operates PoliGrid, a 23 kV microgrid interconnecting 25+ buildings with on-site generation and a 2-km district heating (DH) loop. Core assets are a 2 MWₑ natural-gas CHP (overall efficiency > 82%) and summertime trigeneration via a 1.4 MW absorption chiller; rooftop PV totals ~1 MW and is planned to expand. When campus demand exceeds self-generation, electricity is imported from the grid. Annual consumption is ~14 GWh electricity and 11 GWh thermal, with ~3.3 million Sm³ of natural gas. Thermal demand peaks in Jan–Feb–Dec, drops near zero in Apr–May (and again in Oct), and rises in summer due to chilled-water needs; electrical demand is steadier, peaking in July. All key flows are metered hourly and accessible via an online platform.

The CHP unit is a Jenbacher JMS 612 GS-N.L. (2,000 kWₑ). Heat is recovered from oil, jacket water, and exhaust, which is cooled from ~350 °C to 120 °C. A diverter valve modulates recovered heat. For the baseline model, the CHP runs continuously hour-by-hour (no start-stop), and cannot go below its minimum load.

Despite optimized dispatch (with PV and electricity sales), more than half of recoverable heat is wasted due to low thermal demand in many periods: of 18.36 GWh recoverable heat, only 8 GWh is used (≈56% discarded, mostly via the CHP diverter). Storing electricity (e.g., BESS) is not favored: excess thermal energy (5.4 GWh), and diverting exports would forfeit revenue critical to low operating cost. The integration goal is therefore to cut gas use, first by offsetting boiler operation, while preserving the economic benefits of current CHP scheduling. Seasonality underpins the case: heat is surplus in hot months and scarce in cold months.

RESTORE proposed solution

This Use Case aims to investigate the role of RESTORE technology in small decentralized DHC networks and to understand the constraints in terms of space in urban contexts. First an evaluation of fuel shifting from natural gas to biogas will be investigated, then the RESTORE concept is implemented understanding the synergies with district cooling operation and RES integration. Final results assess the environmental and economic sustainability of seasonal thermal storage.

RESTORE proposed solution (POLIMI CAMPUS)

Integration Concept

A thermochemical energy storage (TCES) using copper sulfate is adopted. Charging setpoint is 130 °C; discharging is 125 °C. Because hydration needs steam, an extra conversion penalty is modeled (≈72.5%). For the preliminary assessment, constant performance is assumed: HP COP = 5.5, TCES thermal efficiency = 0.725, heat-engine efficiency = 0.1, yielding a round-trip ≈0.4 (no design-specific constraints; storage cannot reschedule the CHP, so this is inherently sub-optimal).

Operation

Charging Mode: When CHP heat exceeds demand, the heat pump upgrades the otherwise-wasted low-temperature heat and stores it in TCES at high temperature (raising useful energy instead of dumping to ambient). If the store is full, the system idles.

Discharging Mode: Two operating modes exist:

- Cover boiler load: when demand exceeds CHP output and state-of-charge (SoC) allows, the boiler is turned off and TCES supplies the DH load; any associated ORC power generation is accounted for.

- Cover total demand: in hot periods (to avoid saturation), both CHP and boiler are stopped, and TCES alone meets thermal demand, activated only when CHP performance (PES) is below a threshold and SoC is sufficient. Initial and final SoC are aligned on a yearly basis.