Use Case 4: Brescia, Italy

General

Alfa Acciai operates one of Italy’s largest electric-arc-furnace (EAF) steel plants in Brescia. High-temperature process stages generate substantial waste heat in the flue-gas path. After primary recovery and filtration, a significant share of this energy is still carried back through the dust-collection (cassa polveri) return lines by a cooling-water circuit. Measurements on the EAF1 circuit (segments F5–F12 and F13 to the lateral dust-box panels) showed return-water temperatures around ~80 °C with thermal-power peaks of ~36–38 MW and sustained averages near ~23 MW—an attractive, but uneven, low-grade source.

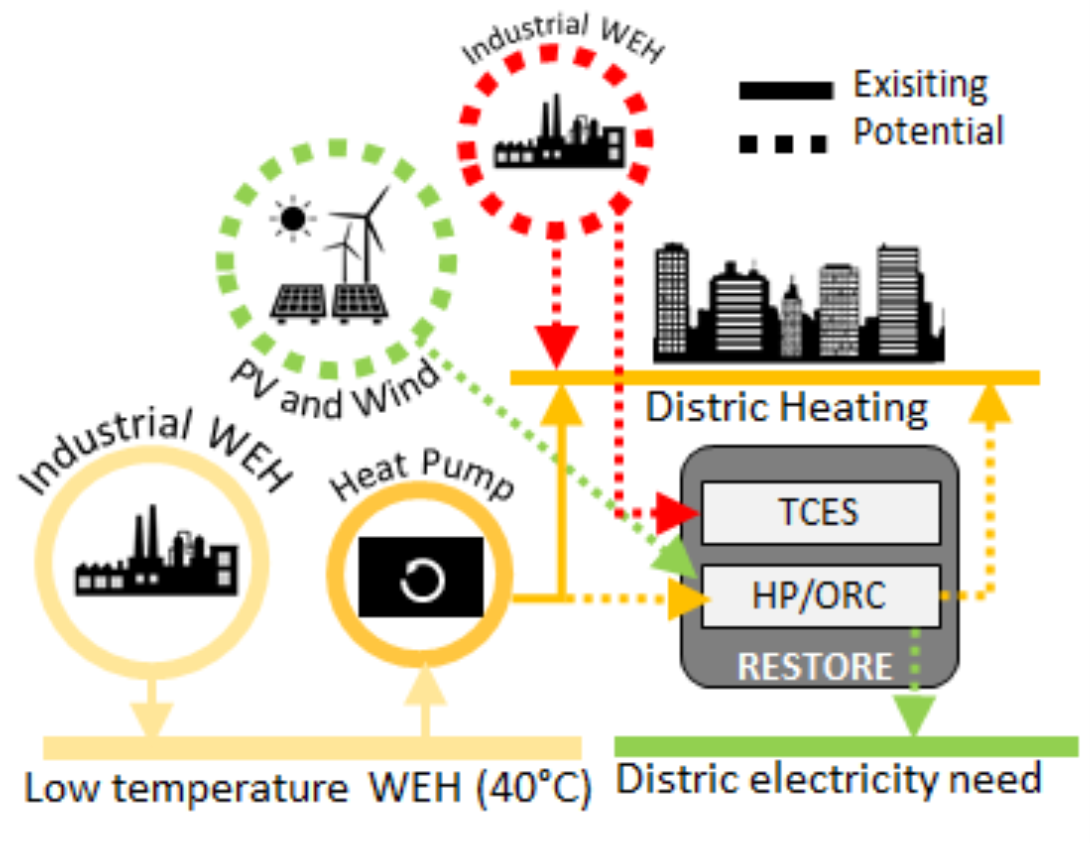

Integration Concept

RESTORE proposed solution (Brescia)

To turn this residual heat into useful energy, the RESTORE configuration couples a large heat pump (LHP) to a Thermochemical Energy Storage (TCES) reactor. The LHP extracts heat from the 80 °C water loop and upgrades it to charge the TCES when waste heat is available and electricity prices are favorable. A deliberate sizing choice balances economics and operability: rather than oversizing to rare peaks, the LHP is set at ~12 MWₜ, which captures >93% of recoverable heat for >96% of operating hours. Flow control on the source loop allows a higher inlet temperature at the heat-pump evaporator, improving COP without compromising overall recovery.

Operation

Charging mode: using cyclopentane as the working fluid, the LHP transfers upgraded heat to the TCES reactor. The reactor stores energy through a reversible thermochemical reaction, effectively decoupling when heat is harvested from when it is needed. Because the source is abundant, the system modulates automatically to maintain stable operating setpoints and match real-time charge demand.

Discharging mode: when heat or power is valuable—e.g., during district-heating (DH) peaks or high electricity prices—the stored energy is released. An Organic Rankine Cycle (ORC), also using cyclopentane and interfacing through the same tank and heat exchanger, converts the reactor’s high-temperature output into electricity. Depending on system conditions, the ORC condenser can either supply the Brescia DH network (raising return water toward the forward setpoint) or reject heat to ambient when electrical output is the priority. The symmetric design of the charge/discharge interfaces supports predictable cycle durations and simplified control.

Benefits

System value: this integration upgrades otherwise lost industrial heat into reliable, dispatchable energy for both power and heat. It reduces gas-fired peak generation, cuts CO₂ emissions, and improves overall plant efficiency—while providing flexibility to follow market signals. In short, the Alfa Acciai TCES use case demonstrates how smart sizing, high-COP heat pumping, and thermochemical storage transform variable EAF waste heat into a continuous, green energy asset for Brescia’s district heating and the grid.