Use Case 3: RESTORE Integration

RESTORE proposed solution

The utilization of the following energy sources will be explored and integrated in RESTORE concept and use to store heat on seasonal base: (i) waste steam in case of reduced heat demand in district heating; (ii) flue gas recovery from boilers at LT which is not used so far; (iii) hot water streams available at site which may be used for water preheating or HP energy input. Expected outcome: huge reduction of the GHG through a high increment in the RES share and the waste heat capacity factor.

RESTORE proposed solution (Mondi)

General

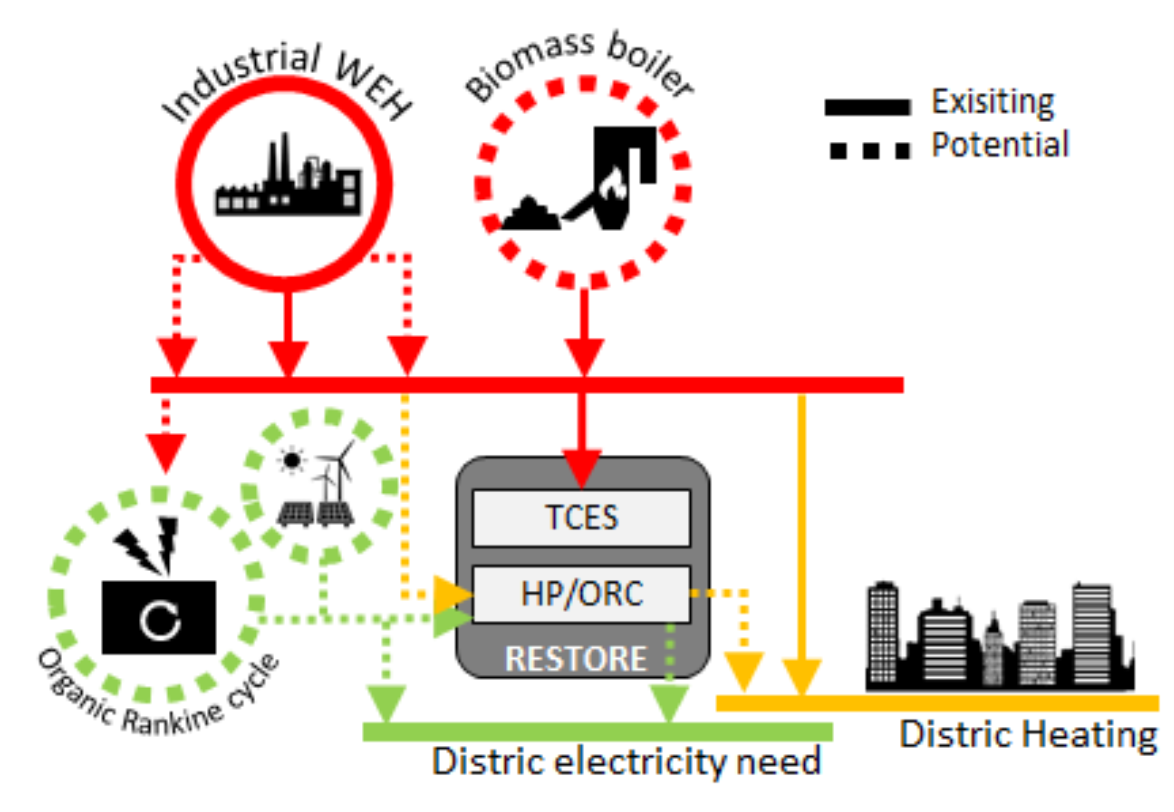

This use case examines integrating a Thermo-Chemical Energy Storage (TCES) system into the MONDI SCP pulp and paper mill in Ružomberok, Slovakia. The mill also feeds the city’s district-heating (DH) network with 5-bar steam that is condensed in a heat-exchange station to produce hot water for the network. The goal is to shift heat from low-value hours to periods with higher DH demand or higher electricity prices, improving the use of renewable and waste/excess heat and reducing reliance on gas-fired peaking boilers.

Integration Concept

TCES taps surplus 5-bar steam upstream of the existing DH condenser via a controlled branch to a steam-to-thermal-oil HX. That HX lifts an oil loop to ~140 °C, which is the plant-side heat carrier to and from the TCES reactor. On the low-temperature side, TCES ties back into the DH station as an additional oil-to-water HX that preheats DH return (typically ~60 °C) and, together with the existing DH condenser, brings it to forward temperature. A small water storage vessel and a steam/condensate handling line are included to manage the vapor produced/consumed by the TCES reactions without disturbing the mill’s condensate system.

Operation

Charging: When mill steam and/or DH demand create a surplus at 5 bar, the diverted steam heats the thermal-oil loop. The reactor is dehydrated at ≥~125 °C (CuSO₄ example under ambient pressure), while the steam released in the reactor is condensed in a dedicated condenser, with the condensate stored for later hydration. The heat of that condensation—and of any upstream preheating step—can assist DH-return preheat so the existing DH condenser sees a lower load. This allows more of the main 5-bar steam to be routed to the condensing turbine when it is economically attractive, without sacrificing DH supply.

Discharging: When DH demand or electricity price is high, stored material is rehydrated. Water is pumped from the small tank to the reactor; reaction heat is removed via an internal coil, returned by the oil loop to the new oil-to-water HX, and used to lift DH-return toward the forward setpoint. In this layout, the TCES line is prioritized for direct DH heating; any optional power cycle attached to TCES faces a low condenser temperature (~35 °C) that is not well matched to DH-return preheat, so it is typically not the primary path for district-heating service.

Benefits

The site operates with strong daily/seasonal swings: DH heat exported ranges from roughly 5,000 GJ/month in summer to ~30,000 GJ/month in winter, and digester operation intermittently reduces on-site power. Integration is therefore control-driven: (i) open the 5-bar branch to charge when DH demand is low and/or electricity prices are low; (ii) throttle charging and favor turbine flow when power prices rise; (iii) discharge TCES to cover DH peaks so the condensing turbine can keep accepting steam; and (iv) respect plant rules that all condensates are reused internally (>~50 °C) and peak gas boilers run only in the coldest months.