Use Case 2: RESTORE proposed solution

The Gmunden (Austria) cement plant of the Rohrdorfer Group supplies clinker (~1,900 t/day) and is already connected to the local district heating (DH) network. It operates roughly 10 months per year with a planned two-month shutdown (December–January) plus short unplanned stoppages, creating a clear need to decouple heat availability from DH demand.

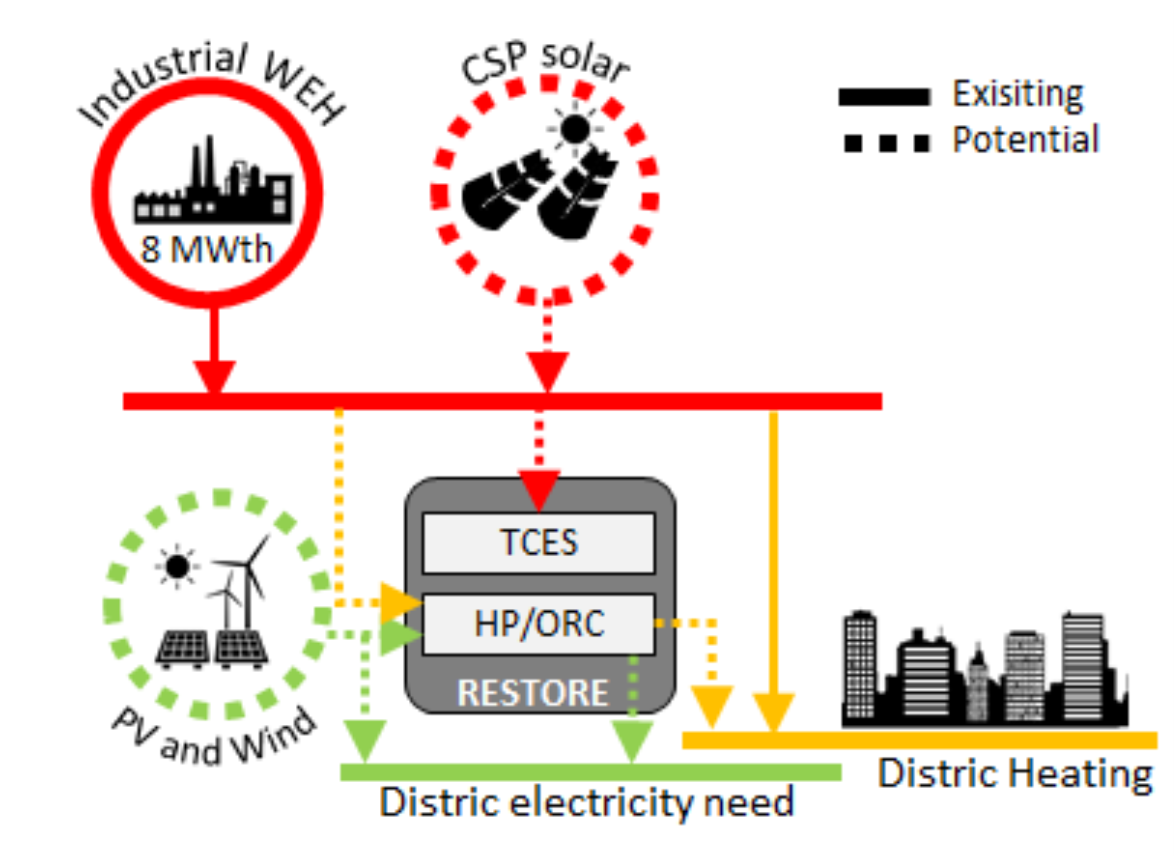

The virtual use case integrates of the RESTORE concept within the industrial plant in order to maximize WEH utilization and RES integration for seasonal storage of heat using cheap off-peak electricity. RESTORE proposed solution Gmunden Community addressed: The Austrian cement industry incorporates nine integrated cement plants and two grinding mills spread across the country, including the Gmunder Zement’s Hatschek plant. The communities involved are the core stakeholders in the site of Gmunden, like adjacent industrial companies, municipalities and regional authorities. Apart from the regional expected impact, RESTORE Use Case II will be a relevant reference on a wider sense, at national and European scales for the cement industry.

The RESTORE concept integrates thermochemical energy storage (TCES) to capture process waste heat and release it on demand to DH. The TCES uses copper-sulfate dehydration/hydration as the storage chemistry.

Main waste-heat sources identified are: A) ~10 MWth dust-laden flue gas at ~400 °C (preferred for charging), B) ~28.6 MWth flue gas at ~130 °C, and C) ~3 MWth around ~100 °C (cement mill). For planning, plant behaviour from 2018 is assumed; DH discharge is targeted mainly during shutdown nights (12 h/day), totaling ~798 h per year.

Operation

Charging (during production): A high-temperature intermediate Rankine loop (cyclopentane) couples the ~400 °C stream to the rest of the system, both protecting downstream components and co-producing power/heat while charging. A large heat pump (cyclopentane, with reheating) then upgrades the intermediate loop’s heat to the TCES reactor at ~125 °C, charging it at ~500 kWth. Simulated performance shows ~6,326 h of annual charging, ~3,163 MWh stored in TCES, ~38,712 MWh delivered to DH during charging, and ~5,521 MWh electricity produced by the intermediate cycle (typical cycle output ≈ 1 MW). Heat-pump COP is ~4 with ~124 kW electrical input for the 500 kWth charge duty.

Discharging (during shutdowns/nights): During hydration, the reactor releases heat at ~105 °C. An ORC (cyclopentane, reheated) conditions this heat and delivers DH supply at ~55/35 °C while generating a modest ~29 kW net electric output. With a discharge setpoint of 500 kWth, the model supplies ~5,259 MWh of heat and ~22.9 MWh of electricity over ~798 h of annual discharge.

Benefits

The configuration reliably covers DH needs during shutdowns, stabilizes heat supply against production variability, and exploits high-grade waste heat more effectively. Storage capacity (TCM inventory) is the main limiter, not heat availability—favouring TCES even for shorter charge–discharge cycles. The existing DH interconnection and the IPSE GO validation indicate strong technical feasibility and replicability.